Fume hoods are a primary method of exposure control in the laboratory. A fume hood is a ventilated enclosure that usually vents separately from the building’s heating, ventilation and air conditioning (HVAC) system and not recirculated into the building. Fume hoods should be used when working with toxic compounds or compounds with a boiling point below 120°C. Fume hoods, or other effective local ventilation, must be provided and used when the materials used will exceed exposure limits in the laboratory.

Standards for determining permissible exposure limits include:

- Occupational Safety and Health Administration Permissible Exposure Limits (OSHA PELs)

- National Institute for Occupational Safety and Health Recommended Exposure Limits (NIOSH RELs)

- American Conference of Governmental Industrial Hygienists threshold limit values (ACGIH TLVs®)

- American Industrial Hygiene Association Workplace Environmental Exposure Limits (AIHA WEELs)

Types of fume hoods

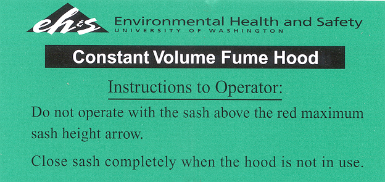

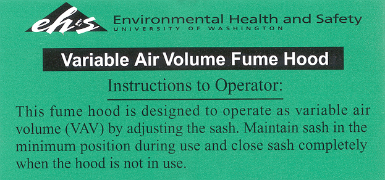

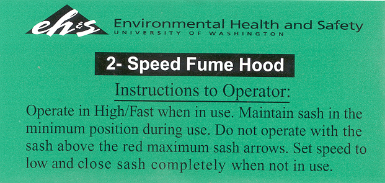

Types of fume hoods at the University include chemical, radioisotope and perchloric acid hoods, with various airflow controls. Fume hood controls include constant air volume (CAV), variable air volume (VAV) and two-state (two speed) control. A number of older wood fume hoods and fume “cupboards” are still maintained. The hoods will display a label that identifies what type of ventilation control is employed:

Fume hoods are categorized into one of two groups: 1) standard flow, and 2) low flow. Standard flow fume hoods are designed to operate at 100 linear feet per minute (LFM) at 18 inches sash height. (Note that some legacy hoods were designed to operate at 100 LFM at full sash height, as high as 25 inches). Low flow fume hoods are designed to operate at 70 LFM at 18 inches sash height.

How to use a fume hood

The fume hood can provide adequate protection for most laboratory processes if it is used correctly.

The fume hood must be operated with the sash no higher than the red arrow.

Detailed instructions for use of the fume hood can be found in the Lab Safety Manual.

Fume hood testing and inspection

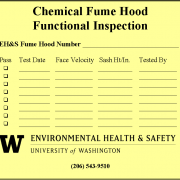

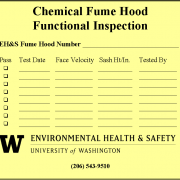

EH&S performs a functional performance test to assure hoods perform as required about every 18 months. The performance test typically includes an evaluation of the face velocity, the sound, containment, monitor performance and the tracking ability of a VAV (when applicable). EH&S may also note any observed problem with controls, sash, baffles, plumbing, light or corrosion.

Fume hoods tested by EH&S will have a label that records its inspection history:

The following definitions are used by EH&S to track the operational status of fume hoods.

If a hood fails an inspection, it may need to be taken out of service until repaired. EH&S will notify the researchers and post a “Do Not Use” sign if repair is required. When UW Facilities has completed repairs, EH&S will retest the hood and put it back in service.